Turned parts

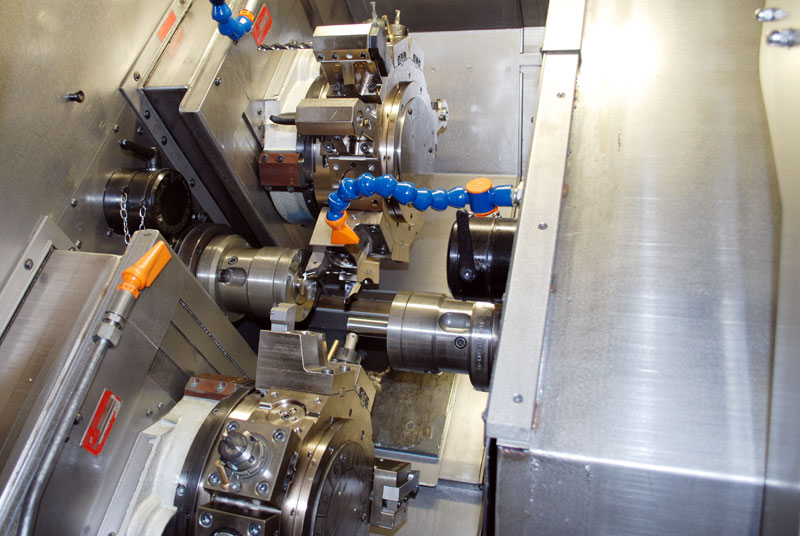

The CNC bar turning workshop is set up for low and medium series production runs with diameters from 5mm to 70mm. The use of special tools allows finished parts to be made, ready washed and prepared for shipping. This production cycle involves a quality control of finished items agreed directly with the customer.

CNC reworking is organised in such a way that the pieces arriving from previous machining processes are reworked, in the form of bars and/or for particular diameters from 70 mm to 120 mm.

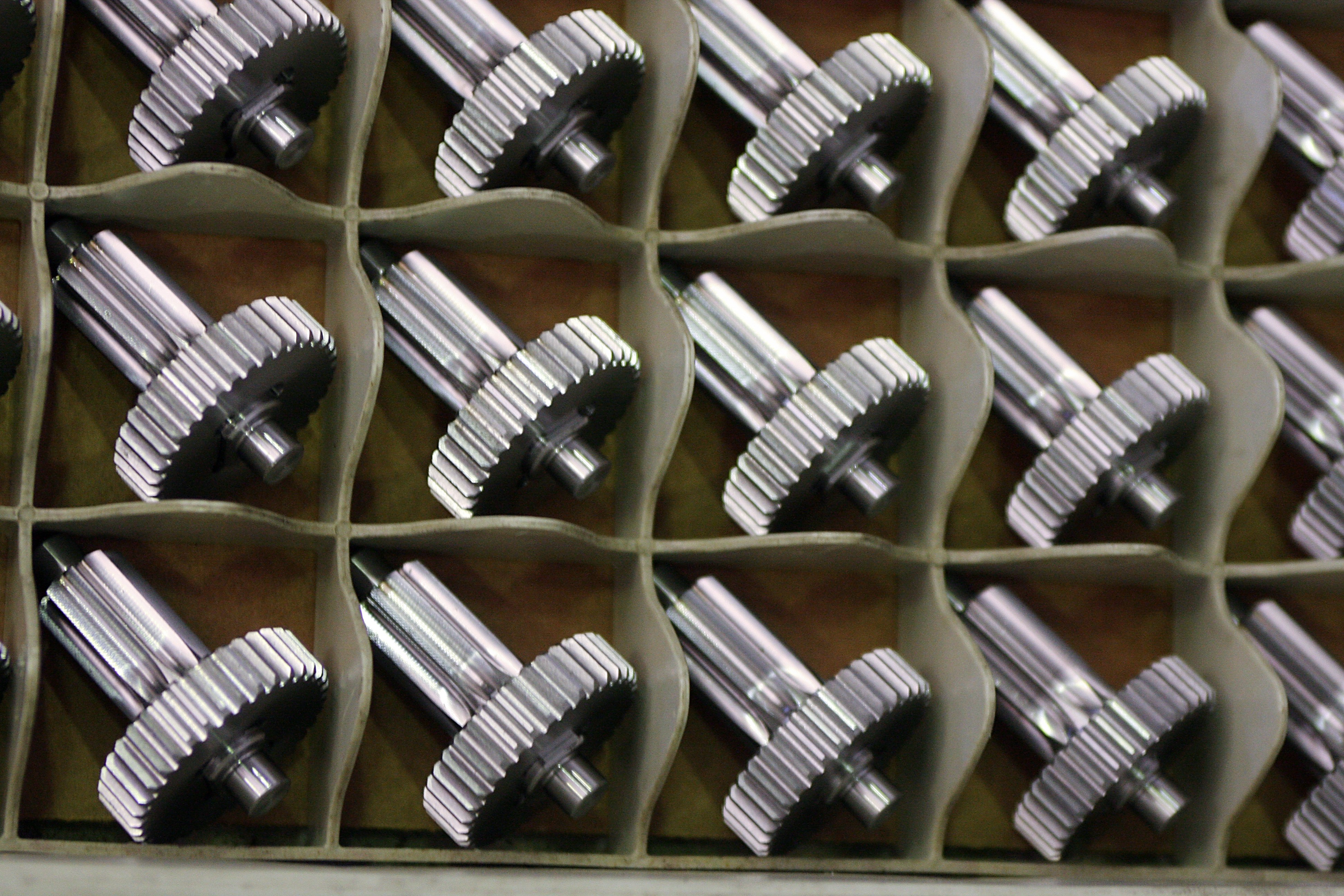

The characteristics of these machining processes guarantee the individuality and precision of the tolerances and especially the surface finishes. At the customer’s request, quality control of up to 100% is available.

All products are thoroughly cleaned and de-greased using a high performance industrial washer, after which they are packaged and prepared for shipping.